Crude peanut oil refinery processing section and machine. Refining processing mainly contains the following sections: Deacidification and Degumming, Decolorization, Deodorization and Dewaxing. Advantages of Lingfine Peanut oil refinery machine Advanced designed edible oil refining process.

Get Price

Crude peanut oil refinery processing section and machine. Refining processing mainly contains the following sections: Deacidification and Degumming, Decolorization, Deodorization and Dewaxing. Advantages of Hongri Peanut oil refinery machine Advanced designed edible oil refining process.

Get Price

Beston crude oil refinery plant mainly consists of heating system, distillation system, dedusting system and electric control system, all of which play an important role in recycling waste oil materials or tyre/plastic pyrolysis oil. Crude Oil Refinery Plant Installed in Dominica Details about the oil refining machine:

Get Price

Peanut oil refinery plant is a set of machines, with which we can get standard edible peanut oil. In the production process of peanut oil refinery plant, we utilize the physical methods and chemical processes according to the different usage and requirements to get rid of the harmful impurities and needless substance in the crude peanut oil.

Get Price

Adding a concentration of 85% food grade phosphoric acid, 0.05 to 0.1% oil, effectively reduces the content of colloidal and trace metals in peanut oil, and at the same time converts chlorophyll into light pheophytin. The reaction time is approximately 25-30. minute.

Get Price

The pyrolysis of lubricating oil waste has been claimed as an alternative to incineration because valuable products are obtained [19]. Literature reports several papers on pyrolysis of waste engine oil [35-37]. The aim of this study is to obtain gasoline like fuel from waste lubricant oil via pyrolysis which can be used in internal-combustion

Get Price

LDPE was also converted at pyrolysis temperature of 900 °C but the produced oil was too viscous and preheating was required in order to reduce the viscosity and use it as fuel in a diesel engine. This result is in accordance with other studies, which have also reported that pyrolysis of polyethylene produced high viscosity oils [7] , [15] , [23] .

Get Price

Renewable Fuel Oil – A Commercial Perspective . Steve Lupton . Technical Information Exchange on Pyrolysis Oil: Potential for a Renewable Heating Oil Substitution Fuel in New England . May 9 – 10, 2012, Manchester, New Hampshire

Get Price

The authors introduced waste plastic pyrolysis oil as an alternative fuel characterized in detail and compared with conventional diesel. High density polyethylene, HDPE, was pyrolyzed in a self-designed stainless steel laboratory reactor to produce useful fuel products. HDPE waste was completely pyrolyzed at 330–490°C for 2-3 hours to obtain solid residue, liquid fuel oil, and

Get Price

tyres are used in the form of pyrolysis tyre oil which is used as a blend with diesel oil, which increases the-efficiency of the engine.The purpose of this work is to compare used tyre pyrolysis oil blends with conventional diesel fuel when fueled in a diesel engine. Before this there is need for survey on various alternate fuels used in

Get Price

Crude peanut oil refinery processing section and machine. Refining processing mainly contains the following sections: Deacidification and Degumming, Decolorization, Deodorization and Dewaxing. Advantages of Lingfine Peanut oil refinery machine Advanced designed edible oil refining process.

Get Price

Crude peanut oil refinery processing section and machine. Refining processing mainly contains the following sections: Deacidification and Degumming, Decolorization, Deodorization and Dewaxing. Advantages of Hongri Peanut oil refinery machine Advanced designed edible oil refining process.

Get Price

Beston crude oil refinery plant mainly consists of heating system, distillation system, dedusting system and electric control system, all of which play an important role in recycling waste oil materials or tyre/plastic pyrolysis oil. Crude Oil Refinery Plant Installed in Dominica Details about the oil refining machine:

Get Price

Peanut oil refinery plant is a set of machines, with which we can get standard edible peanut oil. In the production process of peanut oil refinery plant, we utilize the physical methods and chemical processes according to the different usage and requirements to get rid of the harmful impurities and needless substance in the crude peanut oil.

Get Price

Adding a concentration of 85% food grade phosphoric acid, 0.05 to 0.1% oil, effectively reduces the content of colloidal and trace metals in peanut oil, and at the same time converts chlorophyll into light pheophytin. The reaction time is approximately 25-30. minute.

Get Price

The pyrolysis of lubricating oil waste has been claimed as an alternative to incineration because valuable products are obtained [19]. Literature reports several papers on pyrolysis of waste engine oil [35-37]. The aim of this study is to obtain gasoline like fuel from waste lubricant oil via pyrolysis which can be used in internal-combustion

Get Price

LDPE was also converted at pyrolysis temperature of 900 °C but the produced oil was too viscous and preheating was required in order to reduce the viscosity and use it as fuel in a diesel engine. This result is in accordance with other studies, which have also reported that pyrolysis of polyethylene produced high viscosity oils [7] , [15] , [23] .

Get Price

Renewable Fuel Oil – A Commercial Perspective . Steve Lupton . Technical Information Exchange on Pyrolysis Oil: Potential for a Renewable Heating Oil Substitution Fuel in New England . May 9 – 10, 2012, Manchester, New Hampshire

Get Price

The authors introduced waste plastic pyrolysis oil as an alternative fuel characterized in detail and compared with conventional diesel. High density polyethylene, HDPE, was pyrolyzed in a self-designed stainless steel laboratory reactor to produce useful fuel products. HDPE waste was completely pyrolyzed at 330–490°C for 2-3 hours to obtain solid residue, liquid fuel oil, and

Get Price

tyres are used in the form of pyrolysis tyre oil which is used as a blend with diesel oil, which increases the-efficiency of the engine.The purpose of this work is to compare used tyre pyrolysis oil blends with conventional diesel fuel when fueled in a diesel engine. Before this there is need for survey on various alternate fuels used in

Get Price

The purpose ofthis study is to review the existing literature about chemical recycling of plastic waste and its potential as fuel for diesel engines. This is a review covering on the field of converting waste plastics into liquid hydrocarbon fuels for diesel engines. Disposal and recycling of waste plastics have become an incremental problem and environmental threat with increasing demand for

Get Price

The aim of this study is to obtain gasoline like fuel from waste engine oil by catalytic pyrolysis which can be used in internal-combustion engines. Petroleum based waste engine oil can be converted into reusable products such as gasoline and diesel fuel.

Get Price

- Pyrolysis oil - Marine gas oil - RME biodiesel - 1-butanol 2.1 Pyrolysis oil Pyrolysis oil or bio-oil is a dark brown free flowing liquid with a smoky aroma. During the fast pyrolysis process biomass is heated rapidly in the absence of oxygen. The decomposition produces vapours which are rapidly quenched to prevent secondary reactions.

Get Price

A wide variety of peanut oil refining machine options are available to you, There are 534 suppliers who sells peanut oil refining machine, mainly located in Asia. The top countries of suppliers are India, China, from which the percentage of peanut oil refining machine supply is 1%, 98% respectively.

Get Price

Waste engine oil is fresh engine oil after some time use become black and sticky by mixing with water or dust or metal powder of the equipment abrasion or other impurities. And waste engine oil is mainly come from vehicles. We know how many and how often we use vehicles in our life, so we could imagine how big is the waste engine oil amount

Get Price

This model is for processing waste motor oil into diesel oil. The output should be above 75%, water percent affect the data obviously. About the end product: The end product can be gasoline, diesel, kerosene, gas and heavier fuel oil when the raw material is crude oil, and also can be renewable lubricating oil and heavier fuel oil.

Get Price

price offer for a continuous 8 T / day pyrolysis line enter: waste plastic, hospital, tire, and rubber. out: fuel oil, black carbon, natural gas Last Updated: Nov 12, 2018 This buyer wants to receive quotations only from Premium Members.

Get Price

In this work, diesel-like fuel extracted from electrical pyrolysis and microwave pyrolysis was used as an alternative fuel for the CI engine. The pyrolysis oil generated by both pyrolysis

Get Price

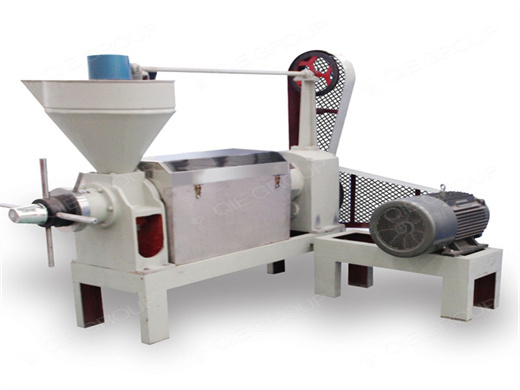

Peanut Oil Press Machine/Peanut Oil Production Line. Time Online:2017-06-13 15:39. Product Description: peanut oil press machine adopt the latest pre-press - oil extraction process technology, at present, this technology is the most advanced in the world, and it makes up for lack of traditional oil press and improve the oil yield, ensu...

Get Price

waste engine oil recycling plant to diesel fuel can be used in black engine oil, crude oil,plastic oil and shale oil, to get gasoline and diesel oil through distilled catalyst. Pumping into the heater with raw material , through the gas,fuel oil or coal heating to working temperature, the maximum working temperature about 410 degree and the

Get Price