Flaxseed Oil Market – Global Industry Trends and Forecast to 2026 | Data Bridge Market Research. Market Definition: Global Flaxseed Oil Market Flaxseed oil is obtained from the ripened and dry seeds of flax plant which is typically yellow in colour. On a large scale, flaxseed is obtained through the solvent extraction process. Get Price

Get Price

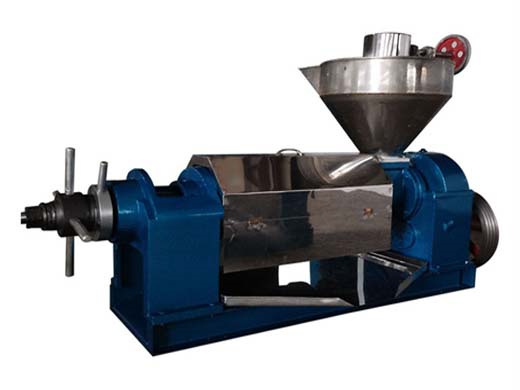

Normal temperature pressing method refers to the flaxseed oil extraction at room temperature under great pressure from physical machinery without the traditional process of high-temperature frying or steaming, so the normal temperature pressed oil still distributes in the undeformed protein cells and contains rich ingredients at three different times .

Get Price

The content of total polyphenol present in the flaxseed was higher than oats. The extracted amount also higher in Soxhlet when compared to the fixed bed extraction method. ... the processes by

Get Price

Supercritical fluid extraction was optimized for the extraction of functional seasoning from mixture of flaxseeds, pepper, turmeric and chilli using Box-Behnken design wherein flaxseed oil generated in situ was simultaneously co-extracted with spice constituents which in turn protected the flaxseed oil against oxidation. The best conditions were 400 bar/62 °C/180 min which

Get Price

The extracted PSG yield from partially defatted flaxseed meal samples varied to a minimum of 7.24% to a maximum of 11.04% when extraction temperature and amplitude level varied

Get Price

Dry extraction of meal is carried out in reaction vessels where meal and heated solvent are given sufficient time for adequate oil extraction. Reduction of the oil content from 10% to 1% in menhaden, pilchard or anchovy meal would require about 4 litres of hexane per kilogramme of meal.

Get Price

Nevertheless, vegetable oil extraction consumes large quantities of hexane, and therefore, there is a need to explore green technologies such as aqueous enzymatic‐assisted extraction and green solvents such as ionic liquids and terpenes .Green solvents present a huge potential to replace the commonly used n‐hexane without compromising the quality of oil and

Get Price

Natural medicines were the only option for the prevention and treatment of human diseases for thousands of years. Natural products are important sources for drug development. The amounts of bioactive natural products in natural medicines are always fairly low. Today, it is very crucial to develop effective and selective methods for the extraction and isolation of those bioactive natural products.

Get Price

Flaxseed Oil Market – Global Industry Trends and Forecast to 2026 | Data Bridge Market Research. Market Definition: Global Flaxseed Oil Market Flaxseed oil is obtained from the ripened and dry seeds of flax plant which is typically yellow in colour. On a large scale, flaxseed is obtained through the solvent extraction process. Get Price

Get Price

Normal temperature pressing method refers to the flaxseed oil extraction at room temperature under great pressure from physical machinery without the traditional process of high-temperature frying or steaming, so the normal temperature pressed oil still distributes in the undeformed protein cells and contains rich ingredients at three different times .

Get Price

The content of total polyphenol present in the flaxseed was higher than oats. The extracted amount also higher in Soxhlet when compared to the fixed bed extraction method. ... the processes by

Get Price

Supercritical fluid extraction was optimized for the extraction of functional seasoning from mixture of flaxseeds, pepper, turmeric and chilli using Box-Behnken design wherein flaxseed oil generated in situ was simultaneously co-extracted with spice constituents which in turn protected the flaxseed oil against oxidation. The best conditions were 400 bar/62 °C/180 min which

Get Price

The extracted PSG yield from partially defatted flaxseed meal samples varied to a minimum of 7.24% to a maximum of 11.04% when extraction temperature and amplitude level varied

Get Price

Dry extraction of meal is carried out in reaction vessels where meal and heated solvent are given sufficient time for adequate oil extraction. Reduction of the oil content from 10% to 1% in menhaden, pilchard or anchovy meal would require about 4 litres of hexane per kilogramme of meal.

Get Price

Nevertheless, vegetable oil extraction consumes large quantities of hexane, and therefore, there is a need to explore green technologies such as aqueous enzymatic‐assisted extraction and green solvents such as ionic liquids and terpenes .Green solvents present a huge potential to replace the commonly used n‐hexane without compromising the quality of oil and

Get Price

Natural medicines were the only option for the prevention and treatment of human diseases for thousands of years. Natural products are important sources for drug development. The amounts of bioactive natural products in natural medicines are always fairly low. Today, it is very crucial to develop effective and selective methods for the extraction and isolation of those bioactive natural products.

Get Price

Oil extraction is one of the most critical steps in seed oil processing because it determines the quality and quantity of oil extracted. Optimization of the extraction conditions for each extraction method enhances yield and quality meanwhile a carefully chosen optimization process equally has the potential of saving time and heat requirements

Get Price

In this Argan oil extraction method, the women sit armed with a base rock and a hand-held sharp stone to start over the extraction process. They crack each Argan fruit shell open in a very cumbersome, time- and effort-consuming process to reach the Argan oil-rich kernels. These are then roasted to lightly bring out the flavor and let aside to cool down before they are ground using a

Get Price

Flaxseed Oil Physical Press Line, High Automation Degree . Normal temperature pressing method refers to the flaxseed oil extraction at room temperature under great pressure from physical machinery without the traditional process of high-temperature frying or steaming, so the normal temperature pressed oil still distributes in the undeformed protein cells and contains rich ingredients

Get Price

Over the last three years, the birthing of this project has slowly taken place.From the initial mobilizing work of building relationship with the first Higaonon family to distributing the first citronella mother plants, the participating farmers have gone far in cultivating the crop, a high time to proceed to the essential oil extraction of the product.

Get Price

This oil is generally shallow in color with light or no obvious smell of the original natural flavor of seed. Solvent extraction process can extract almost all the oil with high economic benefit. It is the most popular processing method of the modern oil industry. Flax seed processing technology comparison Cold pressing

Get Price

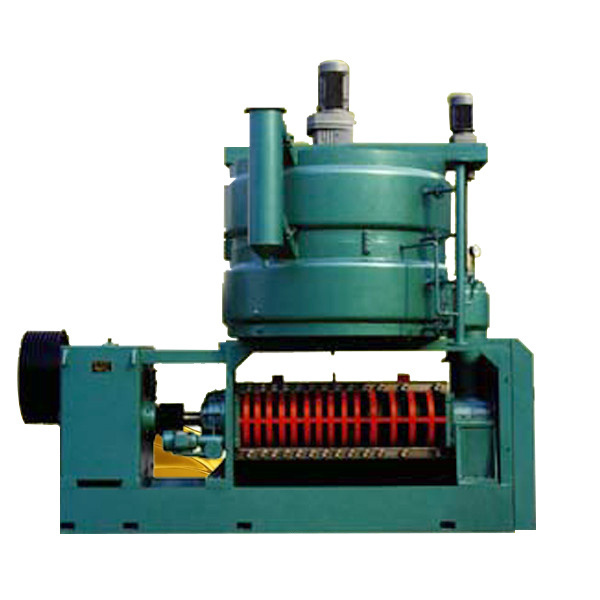

Taking 30 t/d strong-flavor flaxseed oil processing production line as an example, the article introduces the strong-flavor flaxseed oil extraction process through pure physical methods of high-temperature baking, mechanical pressing and low temperature filtering, summarizes the key operating points of main processes and equipment selection, analyses the key factors affecting the quality of

Get Price

Normal temperature pressing method refers to the flaxseed oil extraction at room temperature under great pressure from physical machinery without the traditional process of high-temperature frying or steaming, so the normal temperature pressed oil still distributes in the undeformed protein cells and contains rich ingredients (linolenic acid

Get Price

Flaxseed oil food contains unsaturated fatty acids, including linoleic acid, alpha-linolenic acid, oleic acid, saturated fatty acids and squalene, at a certain ratio of components. The above linseed oil is obtained by a method including machining flax seeds, solvent extraction followed by separation of the oil from the extract.

Get Price

The volatile oil diffuses into the fat, then the fat is collected and the oil is extracted from the fat using alcohol. Once the alcohol evaporates what is left behind is called the absolute . As you can imagine, this is a very time consuming process, but it was the only way to extract delicate flowers like Jasmine for a very long time!

Get Price

Essential oil extraction can be made by traditional or emergent methods; nowadays, mathematical models are being developed for these methods in order to design efficient industrial processes. Although the majority of the essential oils are classified as GRAS, their use in foods as preservatives is often limited due to flavor considerations

Get Price