INDUSTRY: Senegal Senegal Refinery. Company: Energy Allied worked with the Government of Senegal and with Petrosen,Société des Pétroles du Sénégal, the national oil company of Senegal. Size: 60,000 bls/day refinery and 60 MW biodiesel power plant Project Overveiw: Feasibility & Development Study. Key Facts: Energy Allied signed agreements with the Government of Senegal and Petrosen for

Get Price

This Division covers all the necessary plants and equipment for all type of vegetable oils and animal fats refining, for either edible or technical use. Particular care is devoted in this division to the design and for the process parameters optimization, in order to reach the best quality results with the lowest possible consumptions and environmental impact. Great efforts have been made by

Get Price

GFIPL edible oil division is engaged in manufacturing edible oil by solvent extraction and refining processes. This unit was set up in 2003 with an initial production capacity to the tune of 250 MT/day of crushing capacity and 100 MT/day of refining capacity. It has a manufacturing plant at Jaysingpur in Kolhapur District , offering edible oils like Soya, Sunflower

Get Price

Optimize your edible oil refining process Innovative measurement technologies ensure high production performance and plant availability . Edible oil manufacturers face the constantly growing challenges of low margins, fluctuating raw materials quality and changing consumer habits. Improving production performance and driving down operations costs calls for innovative measurement technology

Get Price

Process Description of Edible Oil Refinery Plant. As per the today market research it is being concluded that the market demands the refined edible oil with characteristics such as bland flavour and odour, clear appearance, light colour, Long Shelf Life, Suitable for frying since the Crude Oil obtained does contains many harmful factors like free fatty acids , sediments, gums, odoriferous

Get Price

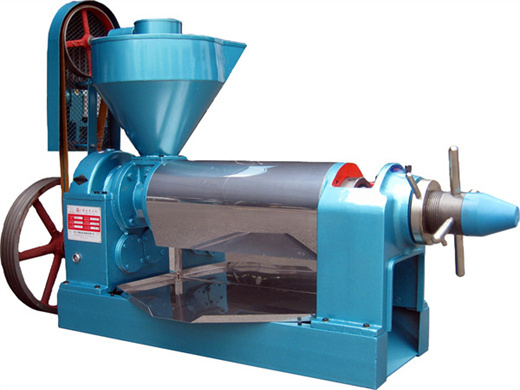

Please note: for self-employed entrepreneur and small-business owner, 1-10 tons/day batch type oil refinery production line is their best choice to refine crude oil into the first or second grade edible oil with features of multi-purpose, easy transportation, small footprint, fewer operators and energy-saving.

Get Price

Technical Parameters of soybean oil refinery plant: Steam consumption: 700KG/T oil: Electric consumption: 28Kwh/T oil : Water 150Kg/T oil: Phosphoric acid: 2~3 kg/T oil: Alkali: acid valuex1-3kg/T oil: Circulating water cooling water yield: 150M3/ Bleaching earth consumption: 3-5Kg/T oil: Waste bleaching earth oil content ≤25~35%: Refining losses: acid valuex1.2 has contacted SACOME to design and manufacture a process plant for the thermal treating of 45.000 kg/h of different types of edible oils within the refining process for one of its factories.

Get Price

Myande Group always focuses on Oils & Fats Equipment quality who devotes itself to improve its study, develop and manufacturing.

Get Price

Edible oil refinery which converts cooking oil into a product that is uniform in taste, smell and appearance, and stability; natural gas processing plant, which purifies and converts raw natural gas into residential, commercial and industrial fuel gas, and also recovers natural gas liquids such as ethane, propane, butanes and pentanes; sugar refinery, which converts sugar cane and sugar

Get Price

Provide the Best Solution of Edible Oil Refining Referring to oil refining, the character of impurities contained in crude oil, and the purpose of refined oil must be concerned. Our Machinery will customize the oil refinery process and solution for each of customer depending on their specific situation and needs. So called “refinery”, generally refers to deacidificationprocess. But in the

Get Price

Edible oil refinery machine - Vegetable Oil Refining. Edible oil refining technology used in edible oil refinery plant is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils. Get Price

Get Price

The crude oil obtained from the solvent extraction device contains impurities which must be removed so that the oil is edible to make it more palatable and more stable to prevent storage. Sesame oil refining plant refers to a series of the refining process, you can remove the oil in the phospholipids, FFA, pigment, bleaching, and other impurities.

Get Price

Date:2019-04-19 / Project / Chat online / Technical support. This 100tpd palm oil refinery and fractionation plant was ordered by our client in Kenya. It is a turnkey project including factory layout, equipment manufacturing, onsite installing and debugging. Now this 100tpd palm oil refinery and fractionation plant successfully installed and run in Kenya. trans Fatty acids <1.5% for oils rich in linolenic acid <1.0% for other vegetable oils Tocopherols: min. 500 ppm Polycyclic aromatic hydrocarbons with features of multi-purpose, easy transportation, small footprint, fewer operators and energy-saving.

Get Price

Oil Refining. Refining produces an edible oil with characteristics that consumers desire such as bland flavour and odour, clear appearance, light colour, stability to oxidation and suitability for frying. Two main refining routes are alkaline refining and physical refining which are used for removing the free fatty acids. The classical alkaline

Get Price

Palm Oil Refinery. Type: Crude Oil Refining From Palm Oil Material: Crude Palm Oil, CPO Capacity: 50-1500T/D Major equipment: Vacuum dryer, Bleaching tower, Deodorization tower, Deacidification tower. Application: High Efficiency Oil Refining From Crude Palm Oil With Low Energy Consumption and Oil Yield. ONLINE CHAT ONLINE CHAT

Get Price

Edible OIl ReFinery Exporters , Manufacturers And Suppliers Chempro Technovation Pvt. Ltd. CHEMPRO has served the edible oil industry since two decades, starting off as a small engineering company offering customized solutions for all aspects of edible oil refining. We through our unique and individualized approach offered cost effective

Get Price

Refining targets for various minor components in edible oils: Minor component: Refining target trans Fatty acids <1.5% for oils rich in linolenic acid <1.0% for other vegetable oils Tocopherols: min. 500 ppm Polycyclic aromatic hydrocarbons (PAH

Get Price